In the building and civil engineering sector, the performance of reinforced concrete structures depends to a large extent on the quality of the connections between the reinforcement. Traditionally, cross-linked bars have been used to anchor steel in concrete. However, with the evolution of construction techniques and increasing demands for compactness, durability and performance, headed bars are emerging as a modern alternative, in line with current standards.

What is an Headed Bar ?

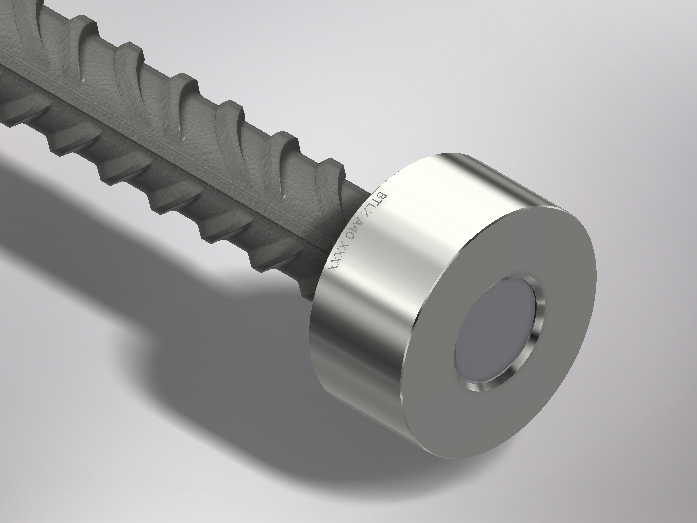

An headed bar is a mechanical element attached to the end of a threaded reinforcing bar. It enables tensile forces to be transmitted directly to the concrete, without the need for a hook or bracket. This principle is based on the uniform distribution of stresses over a larger surface area, in line with Eurocode 2 requirements.

Crossed bar limits

Crossed bars (hooked at the end) are a traditional solution for anchoring reinforcement, but they have significant limitations:

– Difficulty of integration in areas with high reinforcement density.

– Longer fabrication and installation times.

– Need for standard-compliant bending radii (cf. NF EN 1992-1-1 / Eurocode 2).

– Less efficient transfer of tensile forces than modern mechanical solutions.

Advantages of headed bars

1. Enhanced mechanical performance

Headed Bars offer excellent tensile performance, thanks to their ability to transfer forces across a larger bearing surface. Studies carried out as part of ACI 318 show that mechanical anchors provide more reliable load transfer than traditional solutions.

2. Compact and space-saving

Headed Bars eliminate the need for hooks, reducing the space required in connection areas (nodes, columns, footings). This allows better organization of reinforcement and reduces conflicts with other structural elements (gain in compactness recognized in FIB Model Code 2010 publications).

3. Ease of use

Headed Bars, screwed onto threaded bars like those of the BARTEC system invented by LINXION, enable rapid installation without the need for special tools. This reduces labor time and the risk of human error.

4. Improving sustainability

5. Reducing overlap

Unlike conventional solutions, which require long overlap zones, the heads make it possible to avoid such overlap, thus reducing steel consumption and reinforcement volume (studies reported in BAEL and Eurocode 2 design guides).

Current applications

– Thin walls and heavily reinforced columns.

– Concreting resumption zones.

– Low-level footings and slabs.

– Structures subject to dynamic loads.

– Structures in seismic zones.

A solution compatible with LINXION threaded systems

LINXION Headed Bars are designed to be compatible with the BARTEC mechanical splices, guaranteeing mechanical continuity across all reinforcement. They can be combined with standard couplers, special couplers and deviator tubes according to site requirements.

A response to the ecological transition and optimization of resources

By reducing the volume of reinforcement and steel waste, Headed Bars are part of a sustainable construction approach, as recommended by the Stratégie Nationale Bas-Carbone (SNBC).

The use of Headed Bars represents a real evolution in the world of reinforced concrete reinforcement. As an alternative to crossed bars, they offer gains in performance, compactness, speed and durability.

At LINXION The Original, we are proud to offer solutions that have been tested, certified and adapted to the most stringent requirements of the industry.