Headed Bars : an innovative alternative to crossed bars in reinforced concrete structures

In the building and civil engineering sector, the performance of reinforced concrete structures depends to a large extent on the quality…

As part of the RAFAL project, LINXION The Original is developing new rebar bonding solutions for nuclear power plants. This project, carried out in partnership with other players, began in October 2022 and will run for 36 months, with LIXION The Original as lead partner.

The project is funded under the France Relance plan through its R&D cluster, and has been awarded a prize. This government plan aims to accelerate the country’s ecological, industrial and social transformations by supporting companies through subsidies.

The project is supported by EDF and accredited by the Nuclear Valley competitiveness cluster. All the other companies form a large consortium around the RAFAL project.

Towards the end of 2022, LINXION The Original will receive a new 1300kn tensile testing machine, supplied by 3R (Recherches et Réalisations Remy): the SYNTECH 1300. This machine is certified by the “Origine France Garantie” label, which the manufacturer has held since 2012.

The French-certified machine, purchased for R&D purposes in concrete construction, is what might be considered spectacular not only for its capacity but also for its dimensions. Indeed, it has a capacity of 1200 kN in tension/compression, with clamping jaws with a capacity of 1200kN.

As a result, our #rebarsplices can be designed more quickly in R&D. Bartec Group – Linxion is now able to test them according to the world’s different types of steel and international standards.

This machine is equipped with

Machine features:

Since January 2020, BARTEC Group’s concrete reinforcement solutions have become a benchmark for CompaLab, an inter-laboratory comparison (CIL) institute.

Thanks to our excellent test results and numerous certifications, we have become a quality reference for comparisons between different laboratories.

Samples of couplings that were as identical as possible were sent to the CIL institute, which then carried out a series of tests on the participating laboratories. This determines the level of confidence that can be placed in these laboratories, based on their test results.

—— Our news

In the building and civil engineering sector, the performance of reinforced concrete structures depends to a large extent on the quality…

Towards greener, safer construction: how mechanical splices has become a powerful tool in the fight against climate change ? In…

HS2 is a major project designed to revitalize the UK. This ambitious initiative aims to transform the UK’s transport landscape,…

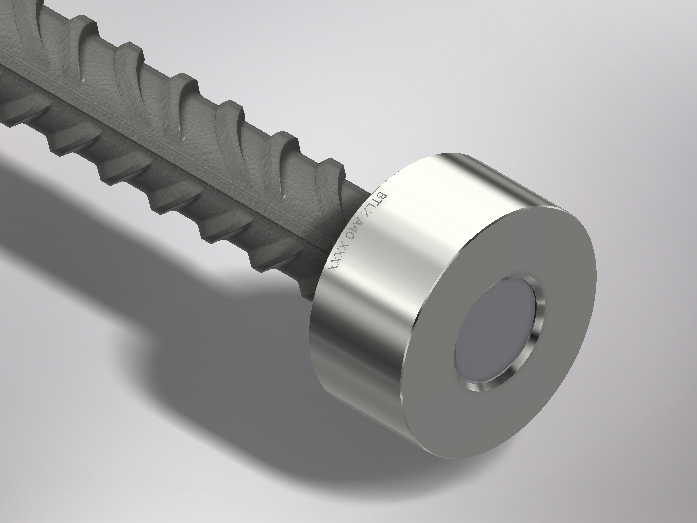

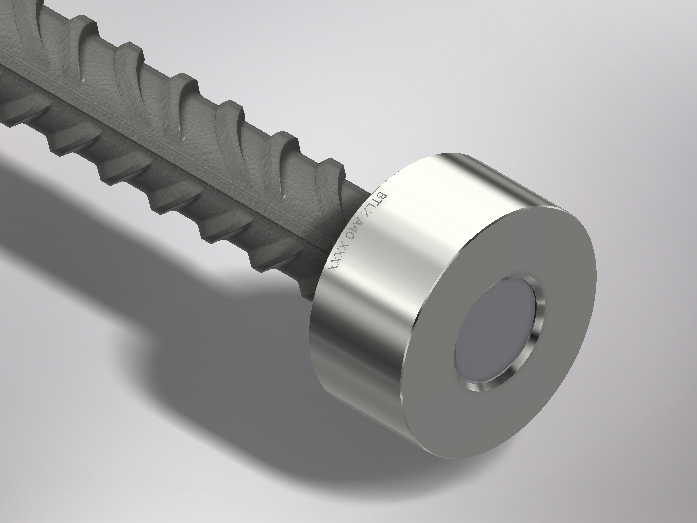

Standard – type C FR

Complies with NFA 35020 and Eurocode 2 fatigue requirements.

Withstands steels with an RM of 700Mpa.

Available and in stock for diameters from 12 to 43 mm.