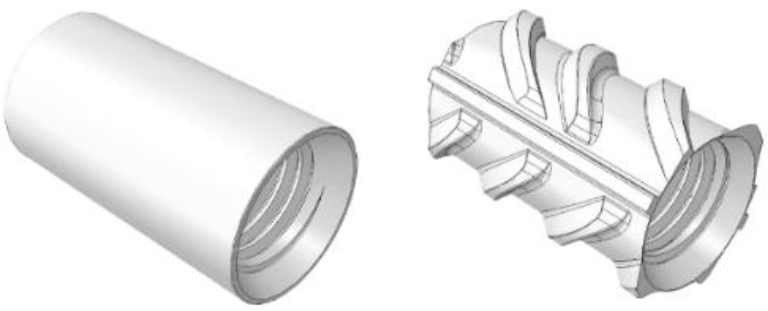

Question: Does the coupler have to be bonding to the concrete ?

Should it have a ribbed surface such as rebars used in construction ?

Does a smooth coupler cause more cracking than a bonding coupler ?

Indirect question: what is the impact of mechanical splices in reinforced concrete elements ?

To answer these question, considerable resources were deployed:

- Creation of a consortium bringing together various complementary parts, each bringing their own skills and expertise in their fields:

- LINXION The Original : Over 30 years’ expertise in mechanical splices, owner of numerous patents in the field, accredited with numerous certificates, iso 15835 specialist, 30 employees. The expert in rebar connection solutions.

- EIFFAGE’s Technical Department : European leader in construction and public works, sales of 20.3 billion euros, committed to innovation, 76,300 employees. The reinforcement and concrete expert in relation to project needs

- LMC² – Université Claude Bernard Lyon 1 : Specialized in the study of composite materials and structures,thanks to the work of researchers at the “Laboratoire des Matériaux Composites pour la Construction”. Expert in construction rules and, rebars and concrete interactions. Location of tests in concrete.

- FOUREAU: specializing in precision machining and bar turning for a wide range of sectors, from medium to large production runs. The machining expert

Participation, observer: EDF – DIPNN – SEPTEN- TEGG Definition of requirements

- Creation of a technical research file called RAFAL.

- The technical project was awarded the NUCLEAR VALLEY label on 28/05/2021.

- In this context, the consortium obtained funding from the nuclear sector investment support fund as part of France relance on October 19, 2021.

- Drafting of a multidisciplinary test protocol for testing in concrete.

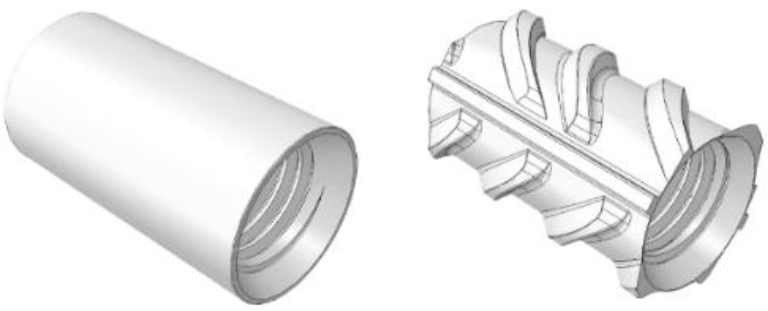

- Realization of couplers in concrete reinforcing bar according to Bartec group patent FR2631028B1.

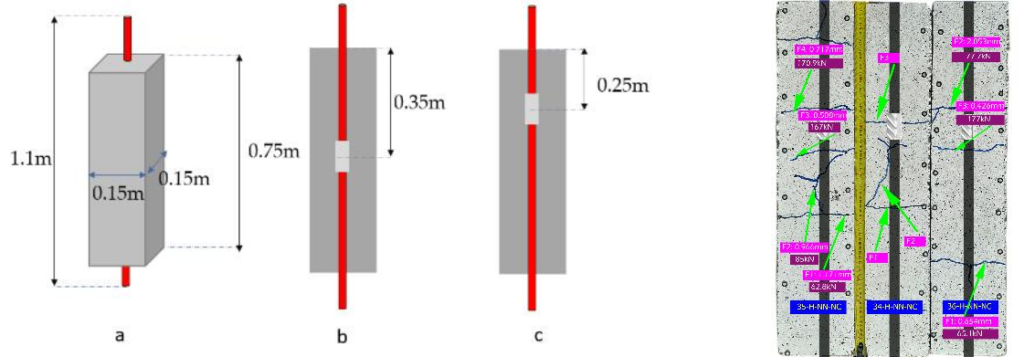

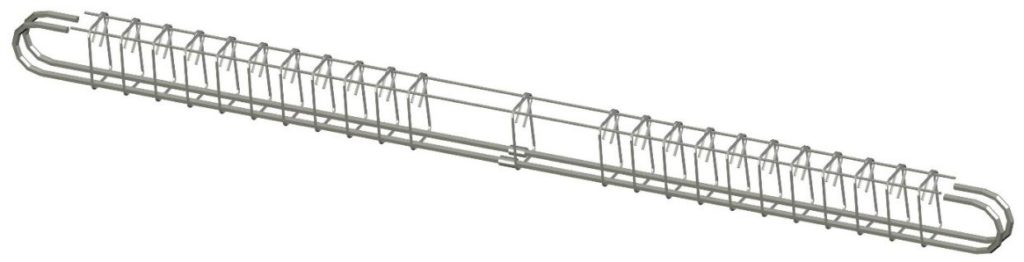

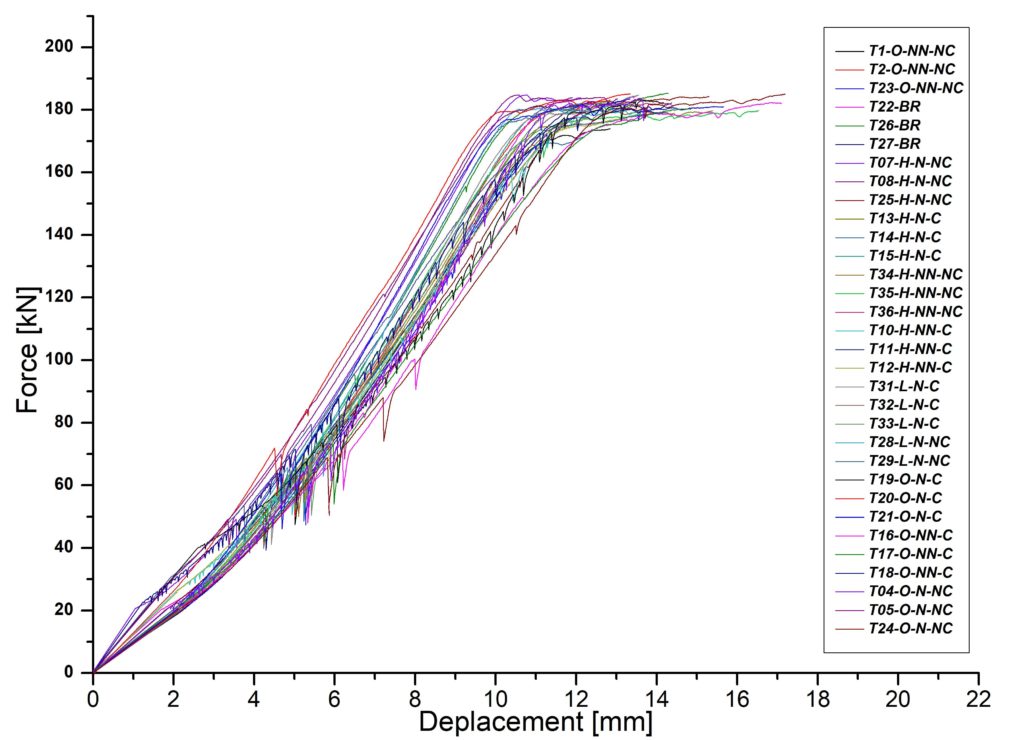

- More than 70 concrete specimens with 20 mm diameter rebar splices were produced for tie-rod tests.

- Over 20 concrete specimens for pull-out tests

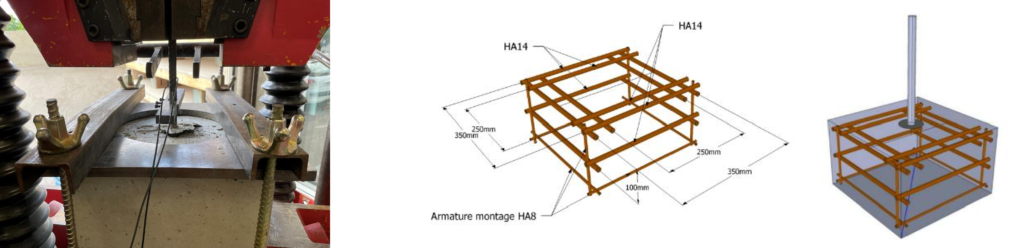

- More than 30 reinforced concrete beams for a 4-point bending test

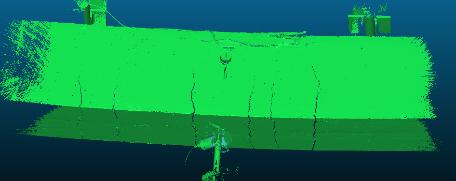

- Investment by the university in a 3D scanner measurement unit to visualize crack spacing and opening, with images also providing good crack mapping.

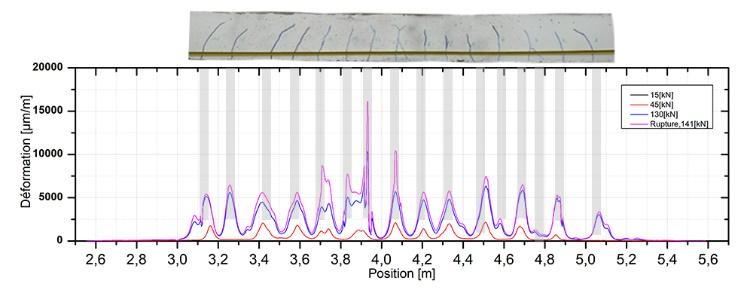

- Analysis of deformations based on experimental results of fiber optic implantation along the steels in the beams.

- More than 60 laboratory tests carried out to ISO 15835 standard.

- LINXION The Original invested in a 1300 KN tensile testing machine for open-air testing to Iso 15835.

- More than 8 test reports written by LMc² University

- 4 tons of steel diameter 20, 15 M3 of concrete, 16 months of design, 20 people, Total budget €4 million

The result: Nothing, it makes no difference whether the coupler is adherent or not, as long as its dimensions remain sufficiently contained in the concrete.

Sometimes it takes a lot of time and investment to demonstrate a claim that has never been studied.

Of course, all of this wasn’t worthless, as many other technical aspects of mechanical splices in concrete have been studied.

The various test reports will be published shortly.

Editor: Richard Boisson Technical Director Bartec group